Welcome to Regenstein – carbon jewelry redefined.

Be inspired by my "Seven Arts" collection and find the perfect accessory that highlights your personality. I look forward to offering you a handmade piece that's as unique as you are!

Seven Arts

-

Caribbean Turquoise

Regular price €99,00 EURRegular priceUnit price €7,62 / per g -

Deep Ocean Blue

Regular price €99,00 EURRegular priceUnit price €7,62 / per g -

Moon Silver

Regular price €99,00 EURRegular priceUnit price €7,62 / per g -

Mountain Copper

Regular price €99,00 EURRegular priceUnit price €7,62 / per g -

Royal Purple

Regular price €99,00 EURRegular priceUnit price €7,62 / per g

Regenstein Design

Design development in 3D

First, the design idea is developed in a CAD system. This results in various drafts, which are then gradually refined until the final form is determined. A sample is then created using 3D printing to test the design for feasibility. Once everything has been verified, the CAD data serves as a template for the production of the investment casting model, and the blanks are cast in stainless steel.

Regenstein Design

Preparation of stainless steel blanks

The stainless steel blanks are carefully prepared. Particular attention is paid to roughening the recess to ensure optimal adhesion for the subsequent insertion of the carbon fabric.

Regenstein Design

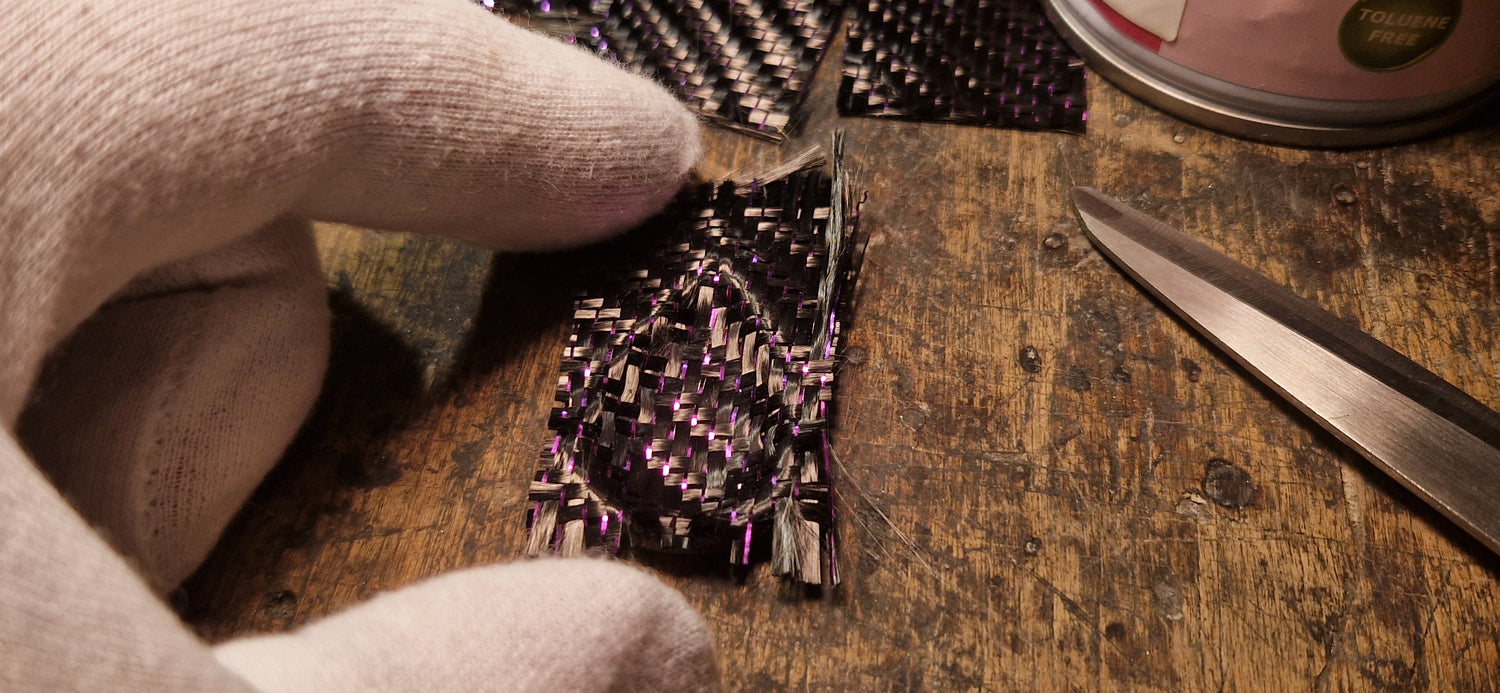

Inserting the carbon fabric

The carbon fiber fabric is first roughly cut, precisely inserted into the recess, and secured with a special adhesive. Excess material at the edges is then precisely sanded off.

Regenstein Design

Resin application and curing

In the next step, the fabric is impregnated with high-quality epoxy resin. The recess is filled slightly above the rim. After a five-day curing period, it is thermally post-cured in a heat cabinet at 65°C for 24 hours.

Regenstein Design

Grinding process – fine work with precision

The most complex step: sanding in seven finely graded grits – from coarse to ultrafine. This process requires patience and experience and forms the basis for a flawless, glossy surface.

Regenstein Design

Polishing – the finishing touch

After grinding, the jewelry pieces are cleaned in an ultrasonic bath to remove even the finest grinding residues – an essential step for a perfect finish.

Finally, each piece undergoes three coordinated polishing steps. The result: a high-gloss, elegant finish that underscores the craftsmanship.

Regenstein Design

The end result – a unique piece with character

After numerous precise steps, a high-quality piece of jewelry with a unique character is created. The combination of polished stainless steel and carbon-reinforced epoxy resin gives each pendant a striking look and a special feel. No two pieces are alike – each is a unique, handcrafted piece that combines precision, craftsmanship, and modern design.